Advantages

- For universal use, independent of the vehicle type and model year

- No waiting for expensive original spare parts

- Increased customer loyalty due to reasonably priced repairs

- No welding, brazing or thread cutting necessary

- In many cases, the faulty line may not even have to be removed

- For 40 years tried-and-trusted by OEMs

- In compliance with EU directive 2006/40/EG

LOKRING

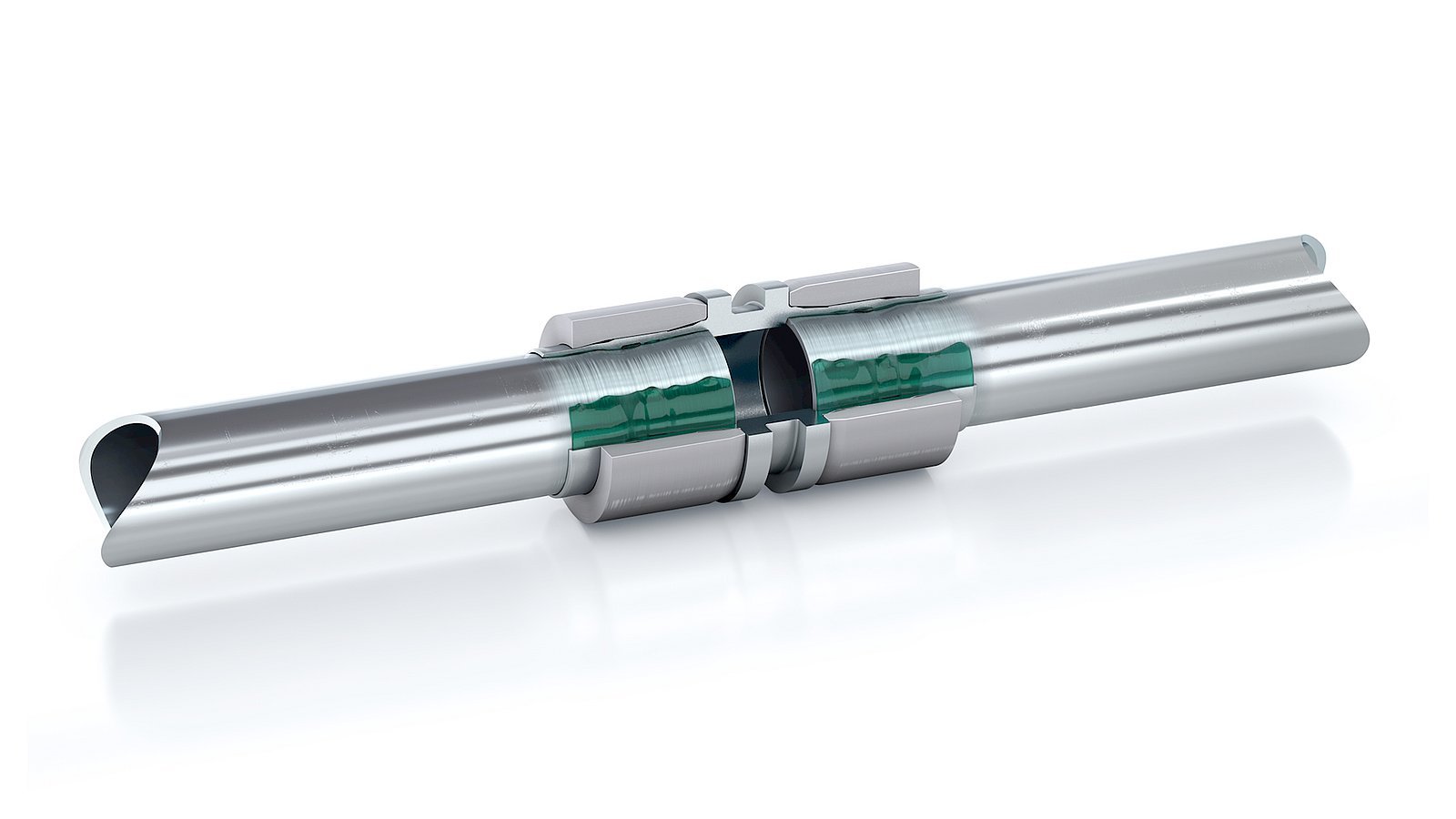

THE TYPICAL LOKRING union joint consists of two LOKRINGs and one tubular joint for the acceptance of the two tube ends. Thanks to the conical inner contour of the LOKRING and the special outer contour of the joint, the diameter of the connection is reduced during assembly to such an extent that the joint and the tube create a hermetically sealed metal-to-metal connection. The lifetime gas-tightness of the fitted connection is ensured by the state of permanent elastic pre-tension, which is produced by the radial forces of the LOKRINGs acting in the opposite direction to the tube-joint connection.

LOKCLIP

LOKCLIP TECHNOLOGY provides you with a simple and low-cost alternative to pressed and screwed connections for hoses. LOKCLIPs can be used to set up both hose-to-hose and hose-to-tube connections for all conceivable repair situations. The system, comprising stainless steel clips, clip position holder and contoured joint practically excludes application mistakes during assembly. Alongside the important SAE J2064, LOKCLIPs meet all the required standards.

Technical Informations

| Reference standards | EN 378-2 and DIN EN ISO 14903 |

| Max. operating pressure | 25 bar |

| Admissible refrigerants | Suitable for R134a und HFO-1234yf. Other refrigerants on request. |

| Temperature range | -50°C up to 150°C |

| Tube diameter range | 6 up to 19 mm (1/16“ bis 3/4“) |

| Approvals | TÜV UL (Akte SA12004) |